Oil & Gas Methane Emissions Monitoring

methane emissions monitoring Enhances Safety, Reliability, and Compliance in Harsh Industrial Environments

Methane emissions in oil & gas operations present critical safety, operational, and regulatory challenges. From upstream extraction sites to midstream processing facilities, operators face demanding conditions that increase the likelihood of gas releases while making detection difficult in those industrial environments. Reliable, real-time methane monitoring is essential to protect personnel, maintain asset integrity, prevent downtime, and comply with increasingly strict emission regulations.

Oil and gas environments expose detection systems to temperature extremes, high humidity, dust, corrosive atmospheres, and remote or inaccessible locations. In these conditions, traditional sensing technologies often fail to deliver the accuracy, response time, and durability required for modern LDAR programs and continuous emissions monitoring.

Challenges for Oil & Gas industrial areas

Operators must ensure safe, reliable, and actionable methane detection across environments characterized by:

Extreme temperatures ranging from subzero conditions to high-heat industrial zones

Condensing or high-humidity environments that affect sensor stability

Dust, sand, salt spray, and corrosive chemicals that degrade equipment over time

Remote or hard-to-access areas requiring autonomous, low-maintenance monitoring

Hazardous zones where ATEX, IECEx Zone 1 certification is mandatory for safety

The need for continuous, quantifiable methane data to comply with regulatory and ESG requirements

The difficulty of locating the exact emission source, such as defective valves, flanges, or processing equipment in complex industrial layouts

The requirement to quantify methane emissions over time, enabling accurate reporting, prioritization of repairs, and integration into LDAR programs

These constraints make advanced sensing, autonomy, and connectivity essential for accurate methane emissions monitoring.

Our Solutions

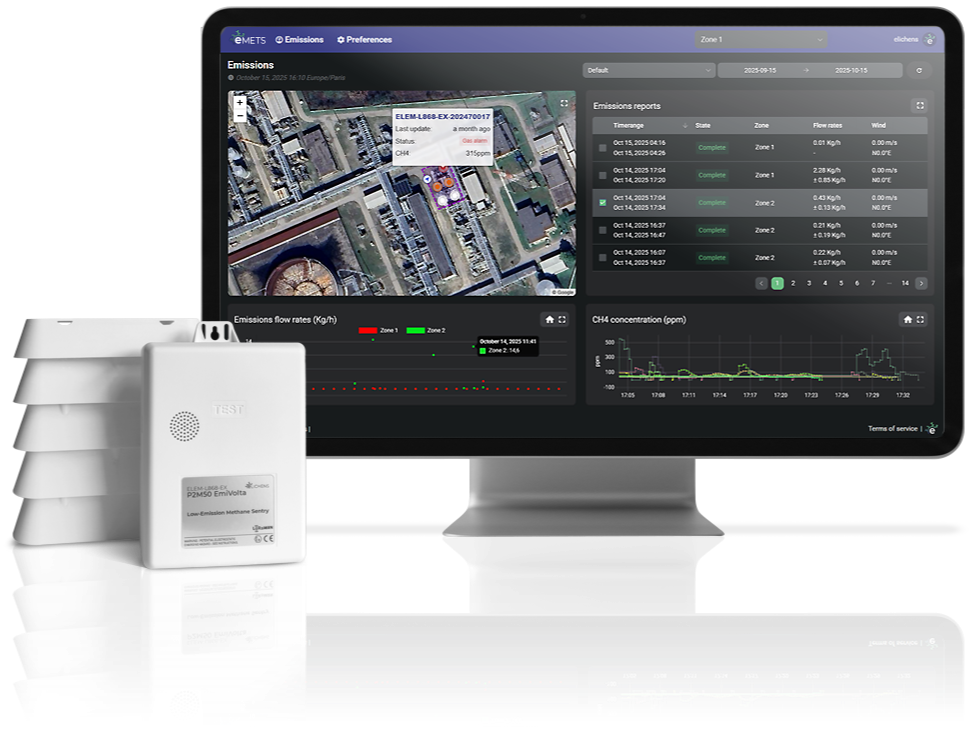

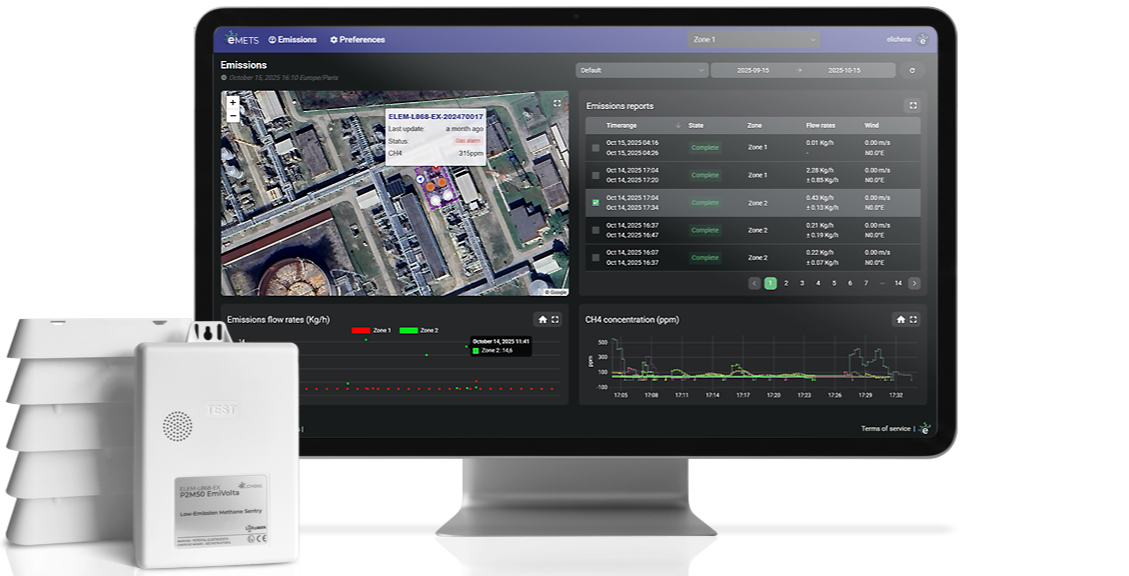

P2M50 EmiVolta – 50PPM LOD ATEX Methane monitor

The P2M50 EmiVolta is an intrinsically safe, industrial-grade methane low-emissions monitor designed specifically for oil & gas facilities with a limit of detection of 50ppm.

Certified ATEX & IECEx Zone 1, it withstands the harshest conditions while delivering high-precision, low-power, continuous methane measurements.

Key Features:

Certified ATEX / IECEx Zone 1 for hazardous industrial areas

High-accuracy methane detection based on proprietary eLichens NDIR technology

Ultra-low power design enabling 10-year of on-site safety with no maintenance

Resistant to extreme temperatures (-40 to +60°C), high humidity IP67-rated

With a WeatherShield, an environment-proof casing designed to withstand extreme conditions.

Always-connected for real-time alerts and continuous data streams

Ideal for continuous monitoring of methane emissions and LDAR support

P2M50 EmiVolta deployments help operators detect methane events faster, reduce safety risks, and maintain compliance with evolving methane reduction regulations.

eMETS – Quantification & Localization of Methane Emissions

eMETS is an advanced methane emissions AI-powered platform that transforms raw methane concentration data into certified metrics. By combining P2M50 EmiVolta, anemometer for wind data, and proprietary algorithm, eMETS delivers: , real-time alerts, and sub-meter localization to accurately pinpoint defective equipment, enabling fast notifications and comprehensive regulatory reporting.

Key Capabilities:

Accurate methane quantification

Enabling real-time alerts (phonecall + email)

Sub-meter source localization across complex industrial layouts pinpointing defective equipment.

Scalable for multi-sensor deployments and multi-site monitoring

Compliant reporting and supports ESG objectives

eMETS provides operators with a clear understanding of emission behavior, helping reduce operational risks and optimize maintenance planning.

Complete Methane Monitoring Ecosystem

Together, P2M50 EmiVolta & eMETS form an end-to-end emissions monitoring ecosystem that supports:

Continuous methane monitoring across oil and gas facilities

Real-time alerts for rapid incident response

Quantification and localization for LDAR and regulatory compliance

Scalable deployments across upstream, midstream, and storage operations

Improved asset integrity, operational continuity, and safety performance

This integrated approach gives operators a reliable and future-proof solution for methane emissions monitoring, even in the harshest industrial environments.

Get Started with eLichens methane emissions monitoring Solutions

Contact us today to discover how eLichens can help you get full visibility on your methane emissions. Get in contact with us below.